Genoil Inc.

Genoil is research and development company which has developed a new HYDROGEN FUEL crude oil mixing process which maximizes transportation mileage distance yield by up to 80% from each barrel of hydrogen added crude oil – Miles Per Barrel – no other oil can perform like Genoil. Our “Genoil 1 Synthetic MBP Crude” increases industry profitability by over 30% and we are the only company providing realistic innovative ultra-clean climate solutions for a lower carbon energy future. The company has recently aligned itself with climate friendly partners from the Middle East, worldwide academia experts and industry leaders, who are all committed to improving the environment, efficiency and our world – but who are opposed to environmental initiatives that endanger energy security. With a combined long history of innovation, scientific and operational expertise, Genoil and our partners have the technical readiness to lead the world in breakthrough environmental strategic transitioning.

Genoil’s environmental transition plan is the only environmental solution which doesn’t compromise world energy security and enables countries to safely transition to renewables. When Genoil 1 Synthetic MBP Crude comes online, world oil production can be reduced by 20% or more and this reduced capacity will still meet or exceed the world’s hungry transportation fuel demands while strengthening world energy security. For example, a country which is heavily reliant on imported crude oil can reduce their crude imports substantially, while still meeting local consumption needs. Additionally, due to the current diesel shortage crisis and other product shortages, Genoil is the only quick fix and low cost environmentally friendly solution.

Genoil provided a preliminary commitment of $5 billion LOI to fund our landmark project with the overall goal to significantly boost profits for National Oil Companies and importing countries to increase transportation fuel production output (MPB) from the existing or reduced crude oil production volumes. If approved by Aramco, Saudi Arabia will produce the best quality highest MPB crude oil in the world.

Investor Presentation

Download the latest Genoil Investor Presentation Here

Crystal Oily Water Separator

Manufactured by DongHwa Entec

Genoil 147 Acre Test & Technology Centre

Photos of The Genoil Technology Centre

Media & News

OTCQB Symbol : GNOLF

Our latest news

GHU Hydroconversion Upgrader (GHU), is a sustainable process, that increases the transportation products produced from a barrel of crude oil by + 80%. GHU lowers the cost of refining crude by 50%. Carbon Reduction : our patented process significantly reduces carbon content of a barrel of crude oil.

Tripartite Research & Technical Cooperation: Genoil, and two of the top research institutes in the world, UFA Scientific Research Institute of Petroleum Refining and Petrochemistry, and OJS (VNIIUS) institute have joined forces to establish a world class partnership to research, develop and market cutting edge technologies and patents in the America’s and around the world. The tripartite partnership consortium will concentrate its activities on meeting modern day refining challenges including removal of sulfur compounds (desulfurization), catalytic process of fuel production, and procurement, construction and startup of projects. Raushan Telyashev who was responsible for 800 engineers and all downstream projects at Lukoil is leading this consortium alliance. Genoil is also in exciting discussions with Mexico’s leading Petroleum institute to join this alliance.

Low Sulfur Fuel Oil – 0.1% and 0.5 % IMO LSFO : Independently verified by Lloyd’s Register, Genoil can produce industry consistent high quality ISO 8217:2010 compliant 0.5% LSFO (Fuel Oil). Our goal is to meet worldwide demand and provide shipping companies with one standard product globally, that they are already familiar with. Our process is, environmentally friendly and implores latest fixed bed reactor technology. Since 1897, a variety of different hydro-processing technologies have been developed to enable refiners to meet the continuous tightening sulfur specifications imposed upon the industry. Genoil HDS achieves the best results in the world at greatly reduced costs.

Crystal Separation Technology : Crystal Separators exceed regulations by utilizing a filter-less operation, separating oil from water to below 2ppm! This design can be run continuously for years requiring NO down time and has the lowest cost of ownership on the market. Crystal is certified by the US Coast Guard and the American Bureau of Shipping. With no internal moving Crystal is designed to run 24 hours a day in the harshest environments. With an ultra-compact footprint Crystal is extremely customizable and can be utilized in a wide range of maritime and non maritime based applications. Request a quote

Genoil Latest News

A Whiff of Rotten Eggs May Augur an Oil Shock

planetadmin Sep 28, 2018Eyad H. Alhebe

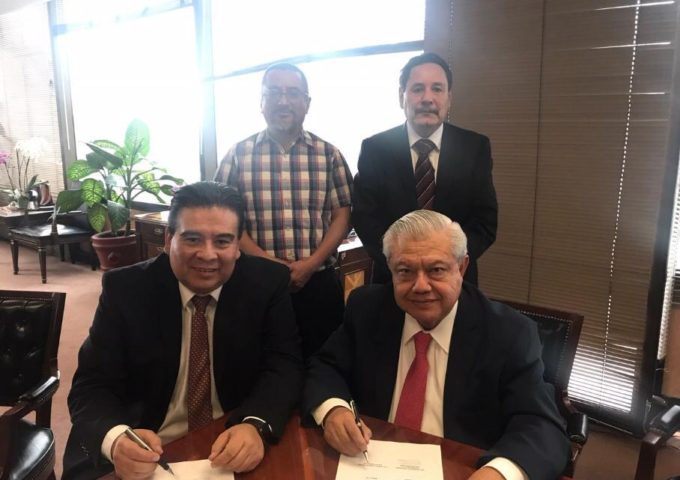

Bruce Abbott Feb 16, 2018Genoil & Complant Ink Deal

Bruce Abbott Sep 27, 2017Alternative Energy Stock Review

planetadmin Sep 05, 2017Genoil on New To the Street

planetadmin May 01, 2017Study: IMO sulphur rules to cost $60bn

planetadmin Mar 02, 2017Major Refinery Project

Bruce Abbott Nov 08, 2016Sea Technology Magazine

Bruce Abbott Oct 21, 2016Setting the Pace

planetadmin Jun 20, 2016Management’s Discussion and Analysis

Bruce Abbott May 16, 2016Ship & Bunker World News

Bruce Abbott Apr 19, 2016Genoil 2015 – 6 K Filing

Bruce Abbott Apr 15, 2016Management Discussion and Analysis

Bruce Abbott Apr 14, 2016Genoil Management Discussion & Analysis

Bruce Abbott Nov 11, 2015Bengt Koch Joins Genoil’s Advisory Board

planetadmin Oct 01, 2014Crystal Sea Redesign

planetadmin Oct 11, 2013Shale Gas – More Problems

planetadmin May 05, 2013BP Energy Outlook 2030 DEEPLY FLAWED

planetadmin Apr 18, 2013Quantitative Easing

planetadmin Apr 01, 2013German Consolidation of Europe

planetadmin Mar 18, 2013Dennis Sears Joins Genoil

planetadmin Dec 01, 2012Brent Crude is UP!

planetadmin Mar 02, 2012NO PEAK OIL -SAUDI OPENING OLD FIELDS

planetadmin Mar 02, 2012Have We Beaten Peak Oil????

planetadmin Mar 02, 2012Latest Oil Developments

planetadmin Mar 02, 2012China Backs Iran

planetadmin Jan 13, 2012Two year Old Manchester Guardian Article

planetadmin Sep 26, 2011Shell chief warns of era of energy volatility

planetadmin Sep 22, 2011Hunt for top-grade crude sources begins

planetadmin Sep 02, 2011Heavy Oil and Oil Sands

planetadmin Sep 01, 2011Sulphurous Crude Price Gap Widens

planetadmin Jun 12, 2011Espo Crude Blend

planetadmin Jun 10, 2011Rising Production of Heavy Crude

planetadmin Jun 10, 2011Coming to an end

planetadmin Jun 09, 2011Welcome to Genoil’s new blog site!!

planetadmin May 18, 2011Genoil Inc. Purchases 147 Acres in Alberta

planetadmin Dec 02, 2010Update on Gulf Of Mexico Spill Response

planetadmin Jun 29, 2010Genoil Inc. Provides 2009 Year-End Update

planetadmin Dec 22, 2009GENOIL INC. ANNOUNCES APPOINTMENT OF NEW CFO

planetadmin Apr 29, 2009GENOIL INC. ANNOUNCES GRAN OF STOCK OPTIONS

planetadmin Jan 28, 2009NEW MEMBER OF GENOIL’S ADVISORY BOARD

planetadmin Sep 02, 2008NEW MEMBER JOINS GENOIL’S ADVISORY BOARD

planetadmin Aug 11, 2008GENOIL INC. ANNOUNCES MEETINGS IN BEIJING

planetadmin Jun 24, 2008GENOIL INC. PROVIDES UPDATE

planetadmin Jun 23, 2008GENOIL ANNOUNCES DIRECTOR RESIGNATION

planetadmin May 27, 2008GENOIL INC. ANNOUNCES BRIDGE FINANCING

planetadmin May 12, 2008GENOIL INC. ANNOUNCES PRIVATE PLACEMENT

planetadmin Feb 27, 2008GENOIL INC. ANNOUNCES DIRECTOR RESIGNATION

planetadmin Oct 19, 2007GENOIL INC. ANNOUNCES ISSUANCE OF SHARES

planetadmin Jun 20, 2007PALM BEACH, FL–(MARKET WIRE)

planetadmin Apr 27, 2006Genoil provides update on Silver Eagle

planetadmin Mar 09, 2006Partners, Affiliates, Clients & Tests

- UFA Institute of Petroleum Refining – ГУП «Институт нефтехимпереработки Республики Башкортостан»

- OJS VNIIUS – Kazan

- Pemex – Genoil Contractor Registration Certificate

- Anton Oil Field Services

- China National Complete Plant Import & Export Coporation, LTD

- China Harbour Engineering Company LTD. (CHEC)

- Grupo Roales – Mexico

- Beijing Petrochemical Engineering Corp (Division of Yanchang Group)

- Stone & Webster International (Shaw Group) Sold to Technip, 2012

- Conoco Canada Ltd. – download & view best test results in the world

- Lukoil Oil Company – incredible results achieved

- Gulf Canada Resources Limited

- CNPC – China Petroleum Engineering & Construction Corp

- Hebei Zhongjie Petrochemical Group Co. Ltd.

- Fushun Research Institute of Petroleum and Petrochemicals