Marine Oil And Water Separation

Advantages

- NO FILTER(S) complies with 5ppm bilge water discharge regulations.

- PERFORMANCE & QUALITY GUARANTEED BY DONGHWA ENTEC.

- Breaks down emulsions and is unaffected by sludge.

- USCG & IMO approval in accordance with CFR 162.050 and MEPC 107-49.

- Lowest operational costs of any separator on the market.

- Headache Free Operation : Did not exceed 5ppm in classification testing even with 100% oil influent.

- Purifying less than 1ppm before filters in real world conditions without the need for emulsion breaking or polishing units, and without the need for heating.

- Separation is unaffected by chemicals or detergents.

- No internal moving parts offer unsurpassed reliability.

- No impact from ship’s movement.

- Unique six-stage design for high-efficiency and performance.

- Very compact units for applications where space is at a premium.

- Versatility for a wide range of applications.

- Bilge water separation for sea-going vessels.

- Suited for off-shore oil platforms. Gasoline/Diesel service stations airports and parking lots.

- Service agents around the world.

- Suitable for wastewater treatment plants, electrical generation plant.

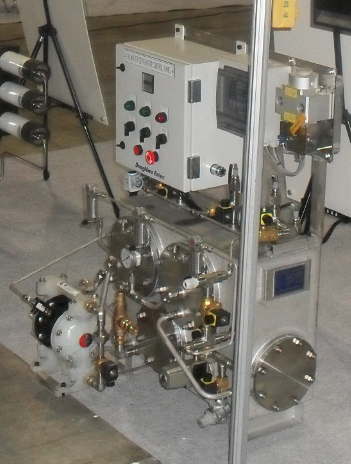

The Crystal Sea oil and water marine bilge water separators designed to be the lowest cost of ownership of any OWS system. Crystal Sea Marine-MU models are the latest generation of our Crystal technology. Crystal Sea separators are state-of-the-art bilge separators which have been certified by the US Coast Guard in accordance with the International Maritime Organization Resolution MEPC 107 (49) in 2007. Subsequently, our bilge oily- water separators have been certified by the American Bureau of Shipping (ABS).

water separators have been certified by the American Bureau of Shipping (ABS).

Genoil Crystal Sea water separators utilize a patented, unique gravity driven process for multi-stage separation of immiscible phases with different densities such as heavier or light oils and water. An innovative oily water separation process combines gravitational and centrifugal forces with surface tension and vortex effect prior to the polishing stage. Our Crystal Sea Unit can separate different oils for recycling purposes if required by the client.

Our advanced automation system ensures unattended operation and features PLC units, self-cleaning oil sensors and fail-safe components. The instrumentation and controls are user-friendly and include carefully selected components for exceptional reliability. In custom-built units Crystal oily water separators can be integrated into complex automation systems being operated and monitored from a central location.

Explosion-proof automation (Class I Div. I) for the oil industry is available upon request.

For immediate pricing or more information call/email: +1 (212) 688-8868 ,

MARINE OWS MODELS

| Model | Max. Capacity (l/h) | (H) Height (mm) | (L) Length (mm) | (D) Depth (mm) | Inlet line (inch) | Effluent Line (inch) | Oil Outlet (inch) | Power (KW) | Weight (kg) |

| MU 2 | 250 | 550 | 600 | 230 | 3/8 | 3/8 | 3/8 | 0.1 | 150 |

| MU 5 | 500 | 945 | 1215 | 485 | 3/4 | 3/4 | 1 | 0.25 | 450 |

| MU 10 | 1000 | 1200 | 1500 | 660 | 1 | 0.5 | 450 | ||

| MU 15 | 2000 | 1415 | 1700 | 780 | 1 | 1 | 0.75 | 900 | |

| MU 20 | 3000 | 1730 | 2200 | 955 | 1 | 1 | 1 | 1 | 1250 |

| MU 30 | 5000 | 1730 | 2200 | 955 | 1 | 1 | 1 | 1.5 | 1350 |

| MU 40 | 10000 | 2200 | 2800 | 1200 | 2 | 1 1/2 | 1 1/2 | 3 | 2200 |

|

||||||||||||||||||||||||||||

* The information posted on this site was considered accurate at the time of posting and it may be superseded by subsequent disclosures or become inaccurate over time.